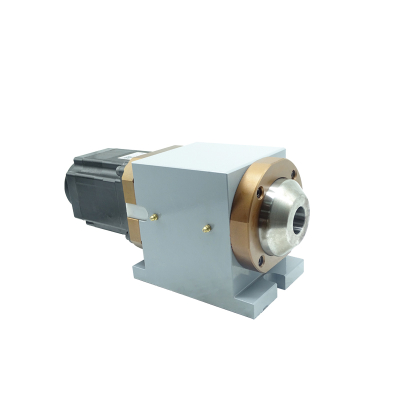

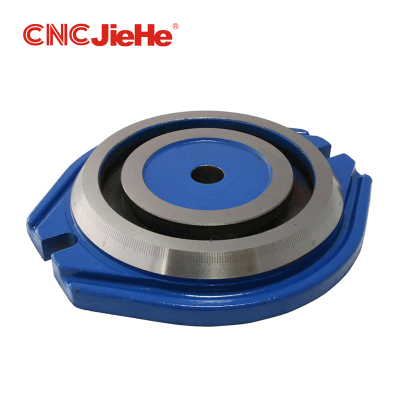

HSK32 40ES Hydraulic Chuck

HSK40.50E Hydraulic Chuck

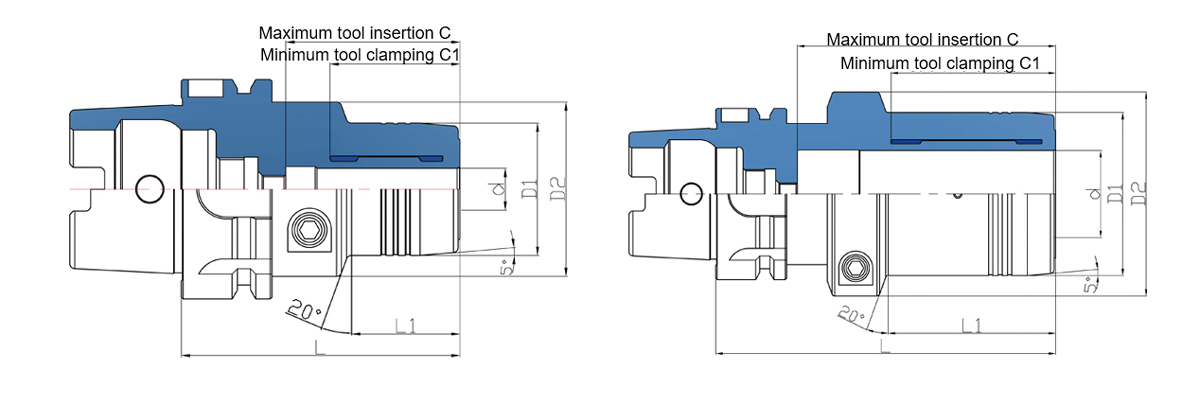

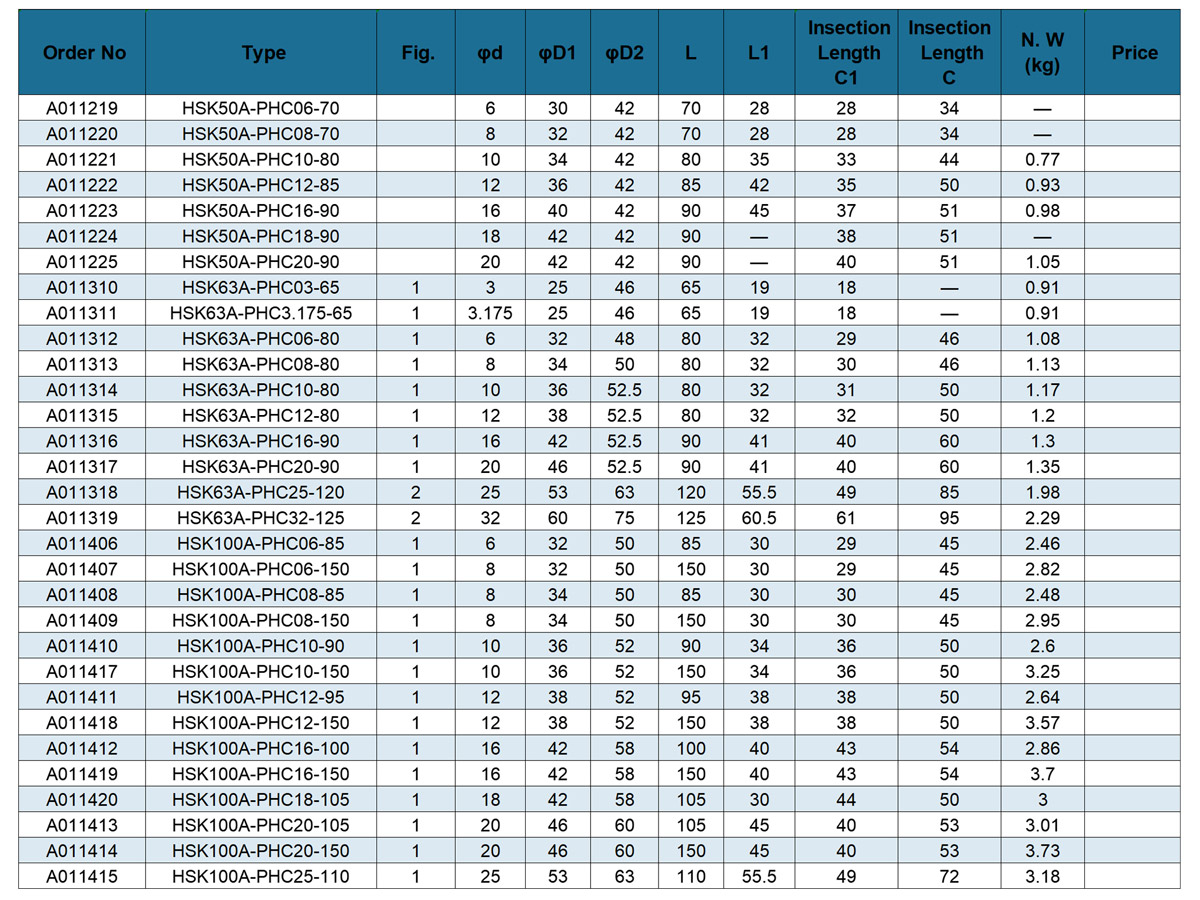

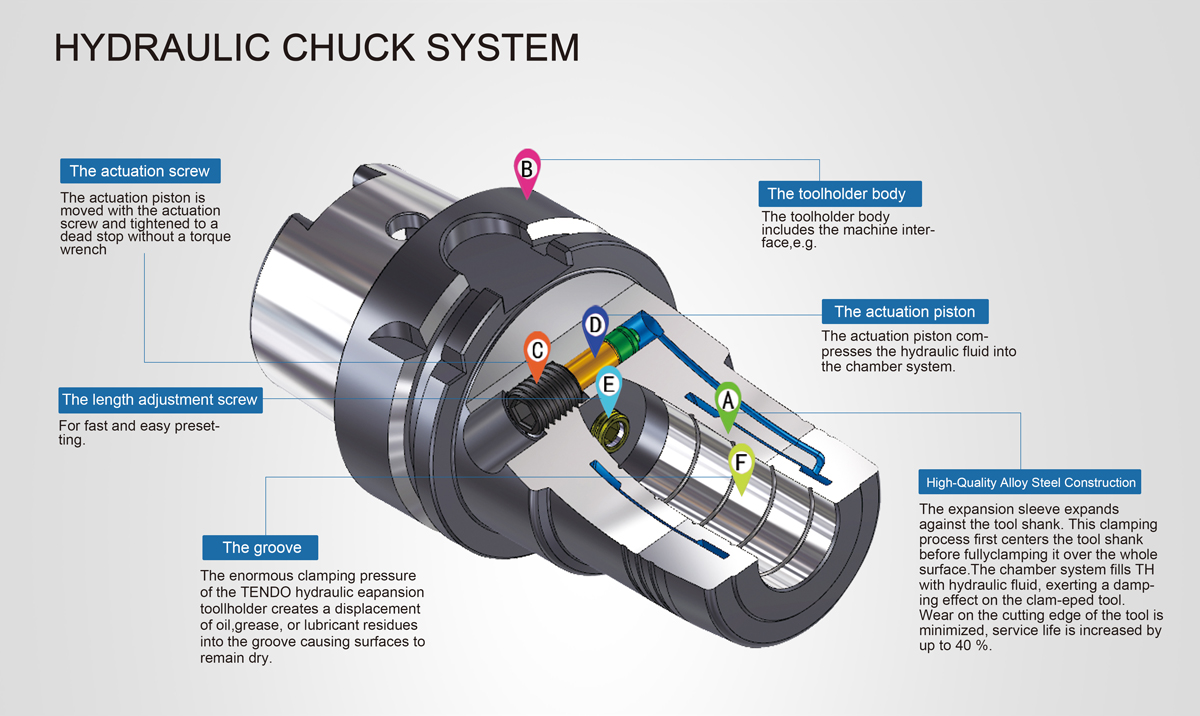

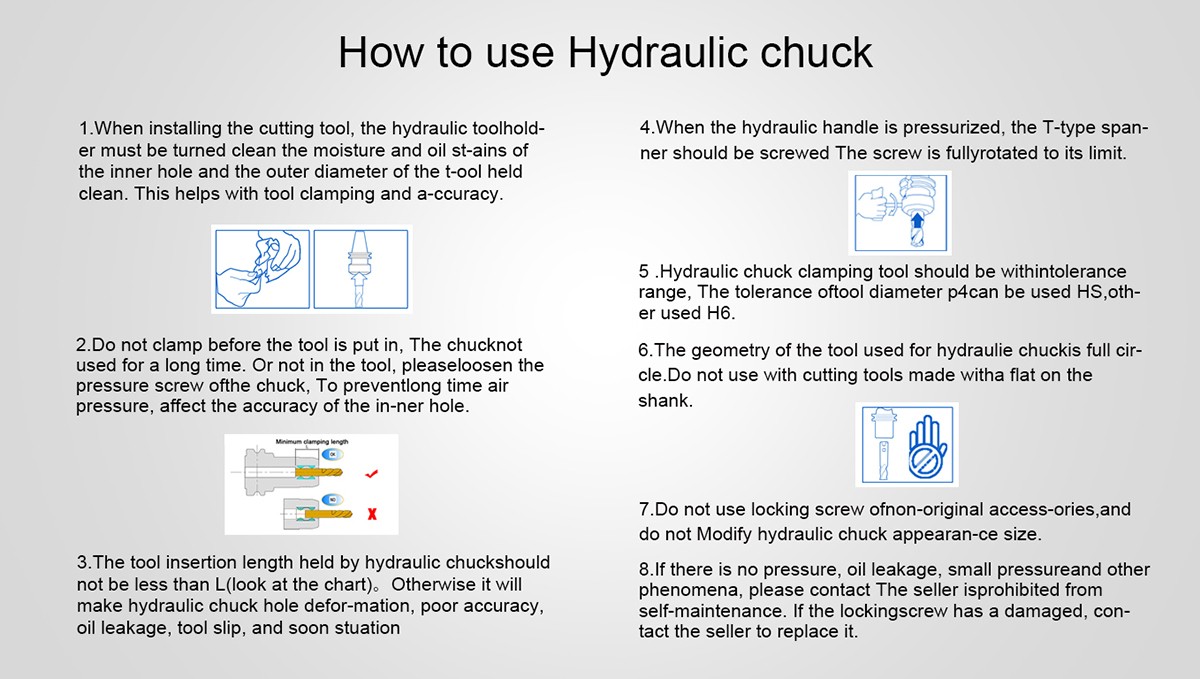

HSK50A 63A 100A Hydraulic Chuck

HSK63A 100A

HSK63F

HSK Slim Type

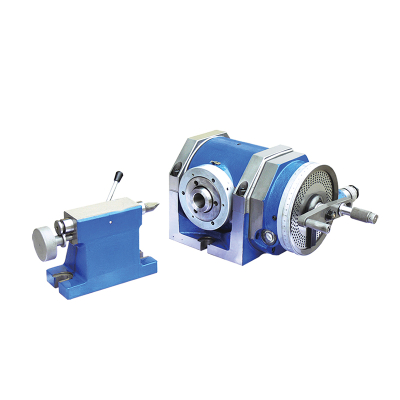

AG90-ER16F Angle head

AG90-ER16 Angle head

AG90-ER20 Angle head

AG90-ER25 Angle head

AG90-BT40-ER25-56-0 Angle head

AG90-ER32-60-0 Angle head

AG90-ER40-70A Angle head

AG90-10PF-80 Angle head

AG90-BT40 Angle head

AG90-BT50 Angle head

AG90-ER25X2 Angle head

LU-ER25 Angle head

LU-ER32 Angle head

HGU-BT50 Angle head

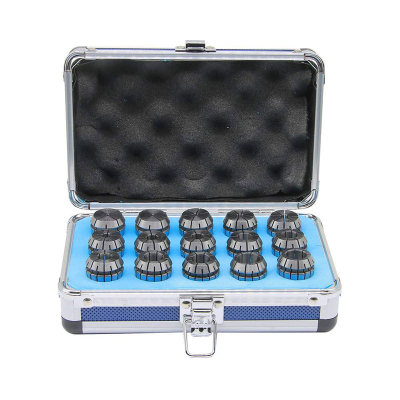

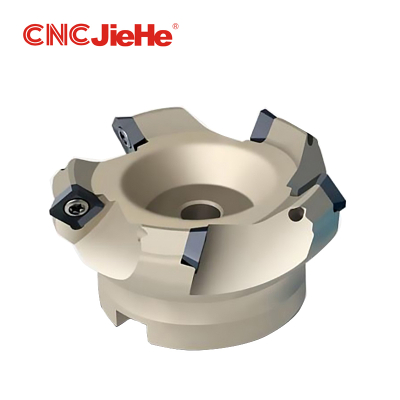

BT ER Collet Chuck Set

CAT ER Collet Chuck Set

MT ER Milling Chuck Set

NT ER Milling Chuck Set

R8 ER Collet Chuck Set

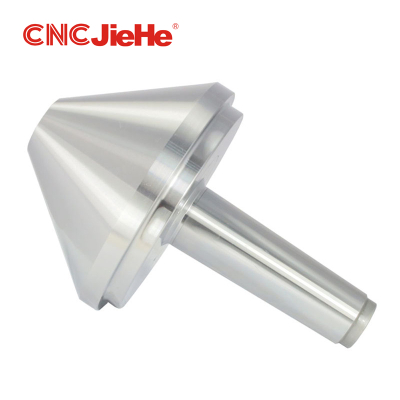

Morse Taper Drill Chuck Arbors

Straight R8 shank Drill Chuck Arbors

Straight Shank Drill Chuck Arbors

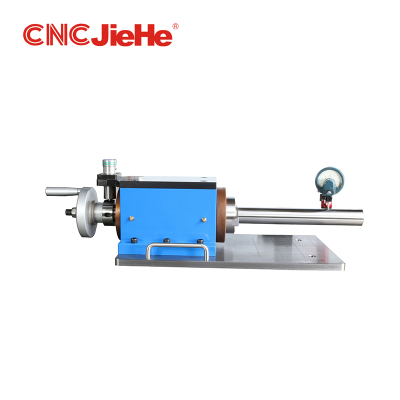

ANCA Special Grinding Wheel Shank for Grinding Machine

ANCA Special Grinding Wheel Shank for Grinding Machine -HSK50F

ANCA Special Grinding Wheel Shank for Grinding Machine -HSK40F

ISOG Special Grinding Wheel Shank for Grinding Machine

Haas Special Grinding Wheel Shank for Grinding Machine-HSK50E

Haas Special Grinding Wheel Shank for Grinding Machine - NT30

Reinecker Special Grinding Wheel Shank for Grinding Machine

Rollomatic Special Grinding Wheel Shank for Grinding Machine

Walter Special Grinding Wheel Shank for Grinding Machine-HSK50

Walter Special Grinding Wheel Shank for Grinding Machine-HSK40E

Walter Special Grinding Wheel Shank for Grinding Machine-NCT30

MAKINO Special Grinding Wheel Shank for Grinding Machine

Hawema Saacke Special Grinding Wheel Shank for Grinding Machine

Hawema Saacke Special Grinding Wheel Shank for Grinding Machine-50A

Made in china Saacke Special Grinding Wheel Shank for Grinding Machine

Made in china Saacke Special Grinding Wheel Shank for Grinding Machine-BT30

Made in china Saacke Special Grinding Wheel Shank for Grinding Machine-BT30CB

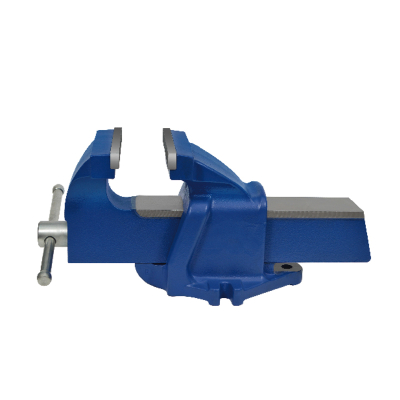

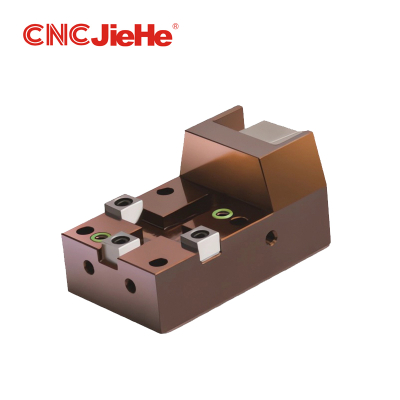

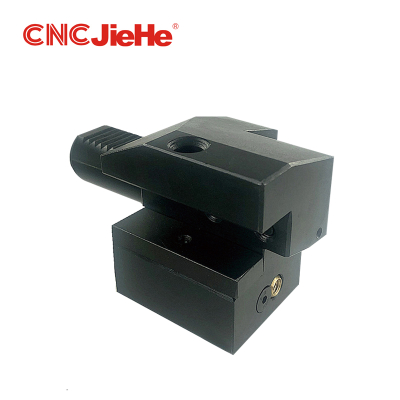

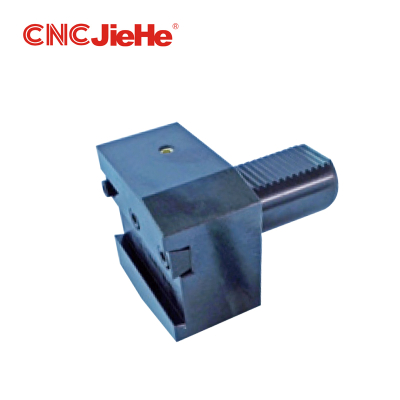

BMT series angled inner hole fixed tool holder

BMT series single-sides oblique outer diameter fixed tool holder

BMT series double side diameter fixed tool holder

BMT series straight double hole fixed tool holder

BMT series reverse outer diameter fixed tool holder

BMT series outer diameter fixed tool holder

BMT series end face fixed tool holder

BMT series boring fixed tool holder