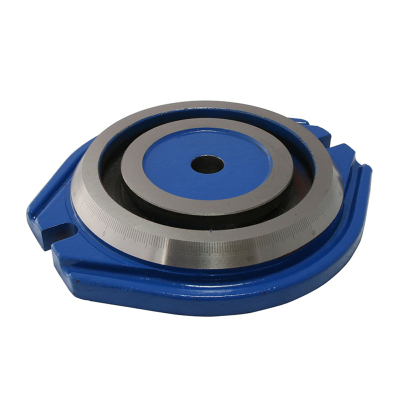

Hydraulic Expansion Sleeve - High-Strength, Precision Shaft-Hub Connection Solution

Hydraulic Expansion Sleeve - High-Strength, Precision Shaft-Hub Connection Solution

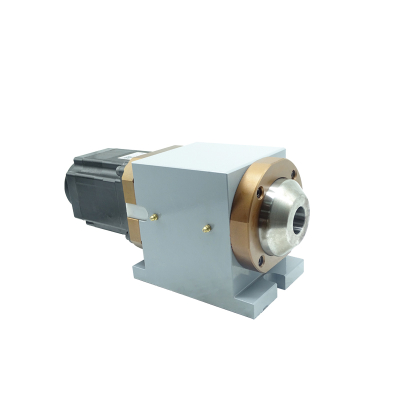

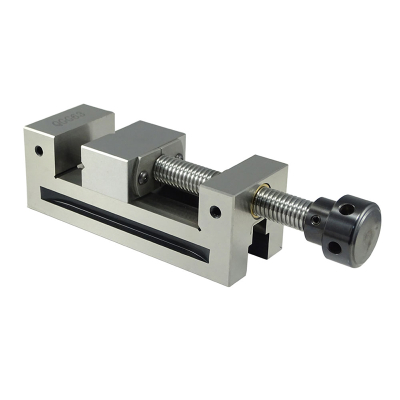

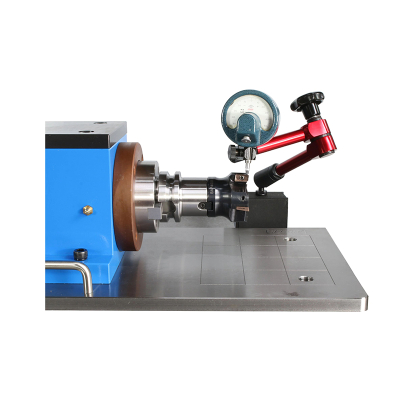

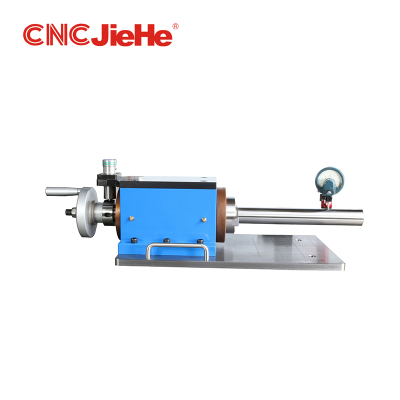

The hydraulic internal expansion fixture uses hydraulic pressure to drive the clamping part to expand inward, thereby securing the workpiece. It is primarily suitable for high-precision, small, and thin-walled parts, and is used in high-precision machining fields such as aerospace technology, hydraulic motor bushing processing, and automotive components.

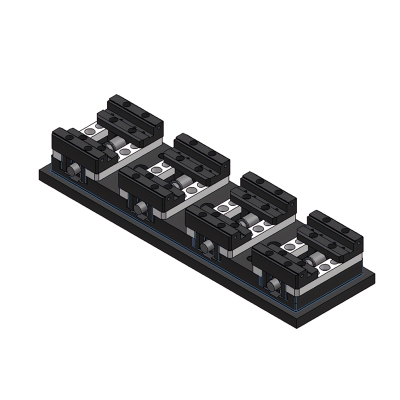

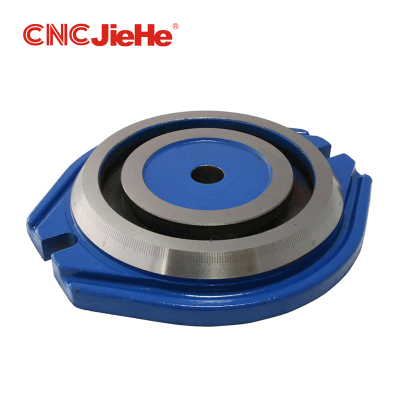

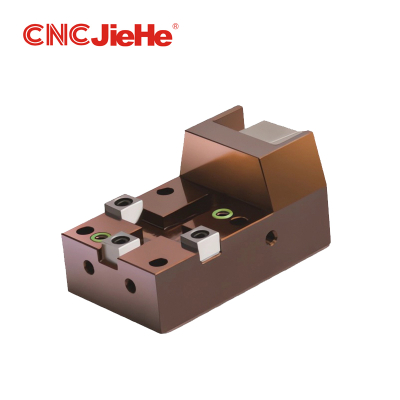

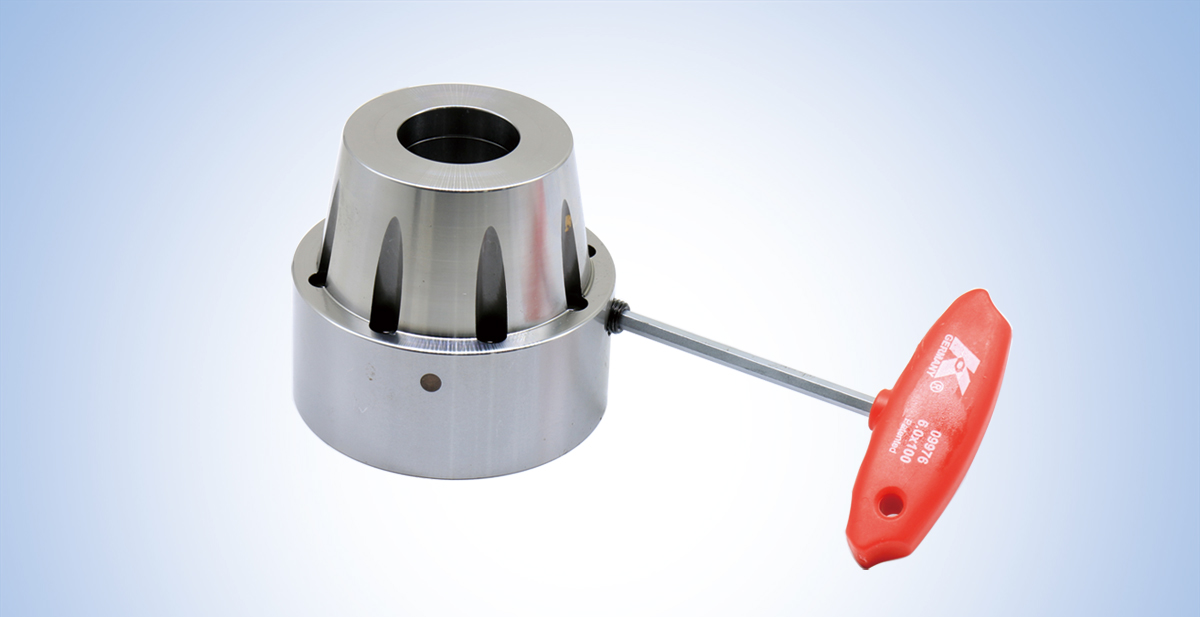

Customizable Hydraulic Internal Expansion Fixture

Product Features:

The fixture offers convenient clamping by simply rotating the locking bolt to secure the workpiece.

It provides high clamping torque, making it suitable for scenarios requiring high cutting forces.

Its strong vibration resistance, enhanced by an internal hydraulic damping system, effectively reduces vibrations during machining and improves the surface finish of the processed products.

The uniform clamping prevents deformation by evenly expanding radially to clamp the inner wall of the workpiece, ensuring the product remains stable.

With high repeat clamping accuracy, the hydraulic system achieves a precision of within 0.003 mm per clamping, making it ideal for ultra-high precision machining.

Additionally, it can clamp products of various outer diameters using reducing sleeves.

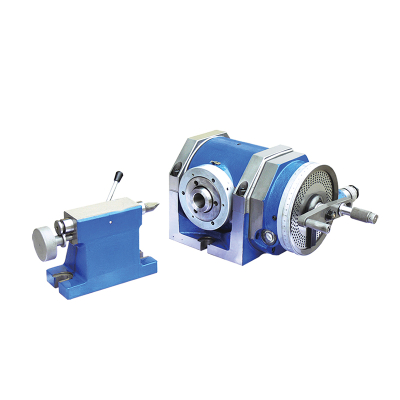

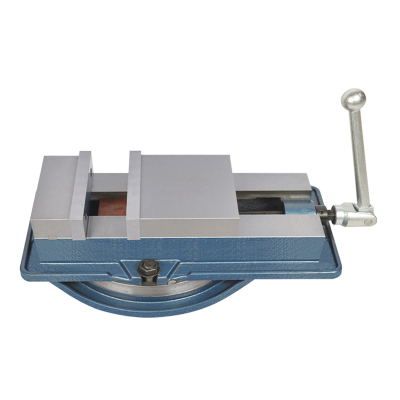

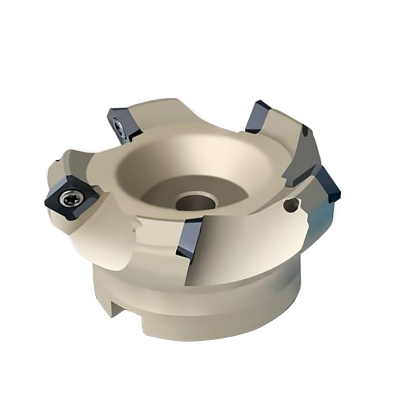

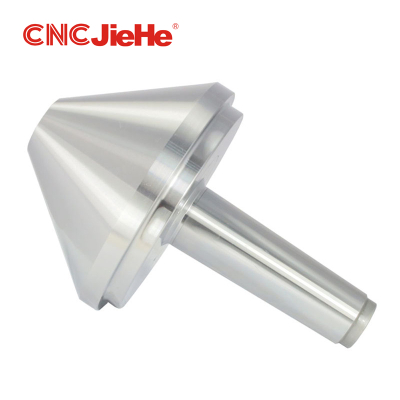

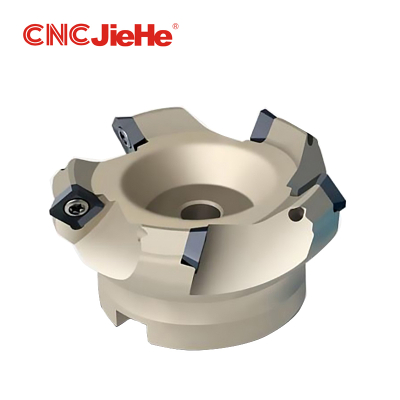

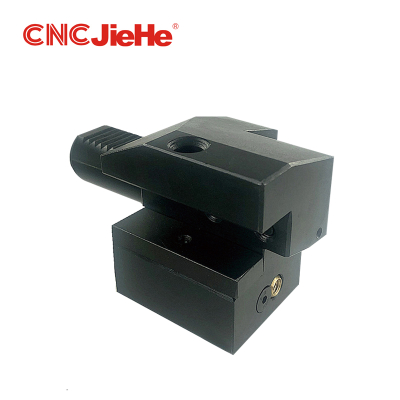

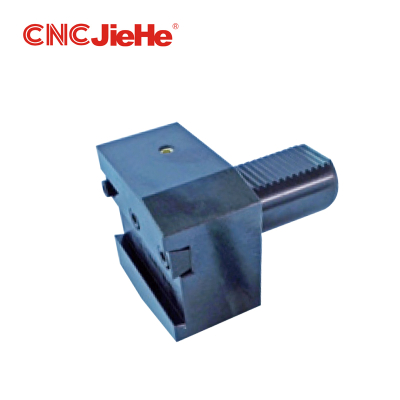

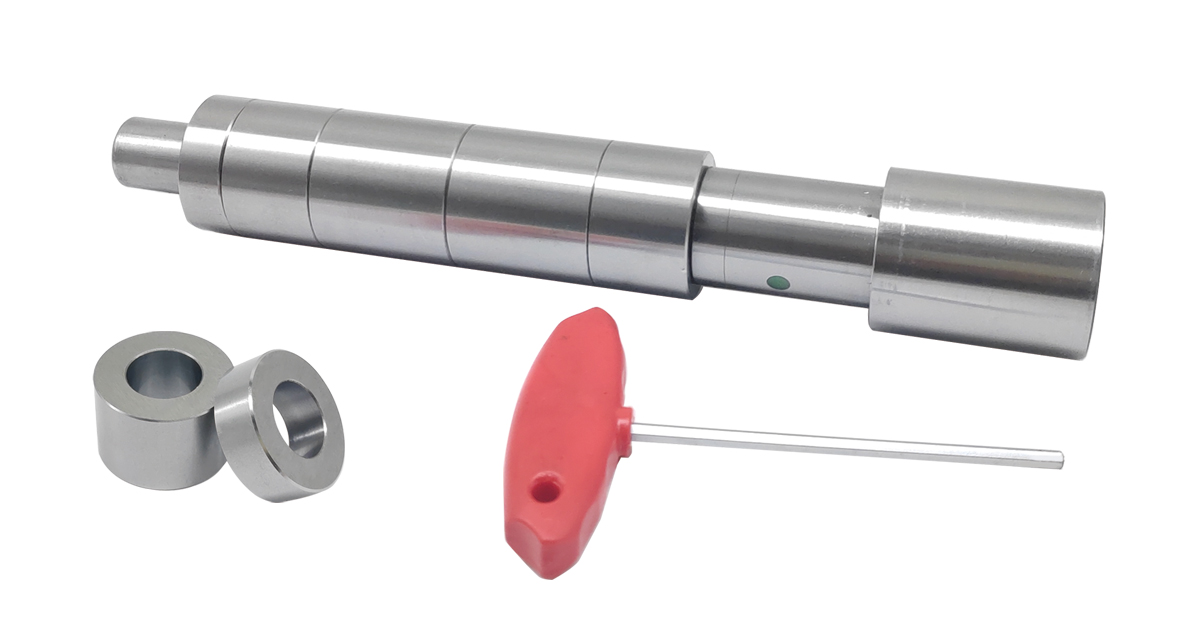

The hydraulic external expansion fixture uses hydraulic pressure to drive the clamping part to expand outward, thereby securing the workpiece or tool being processed. It is primarily suitable for industries requiring high precision, complex shapes, and thin-walled parts, and is used in fields such as aerospace technology, hydraulic motors, and automotive for grinding, high-precision gear milling, and product inspection.

High clamping force, suitable for clamping scenarios with high cutting forces.

Strong vibration resistance, with an internal hydraulic damping system effectively reducing vibrations during machining and improving the surface roughness of the processed products.

Uniform clamping prevents deformation by evenly expanding radially to clamp the inner wall of the workpiece, ensuring the product is less prone to deformation.

High repeat clamping accuracy, with the hydraulic system achieving a precision of within 0.003 mm for each clamping, making it suitable for ultra-high precision machining.

Hydraulic expansion sleeves designed for high-precision machinery. Ensure excellent concentricity and rigidity while minimizing vibration. Custom solutions available to boost your equipment's performance and efficiency!