Innovative Spinning Anti-Vibration Tool Holders: Enhancing Stability and Precision in High-Speed Machining

Innovative Spinning Anti-Vibration Tool Holders: Enhancing Stability and Precision in High-Speed Machining

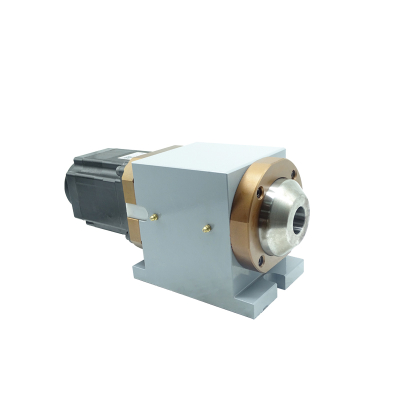

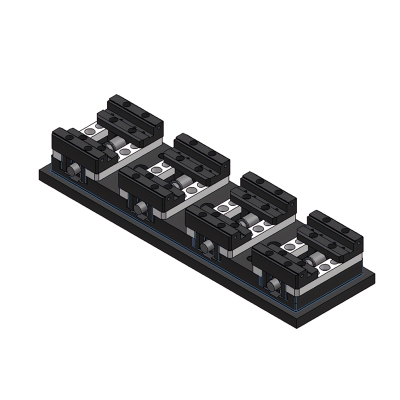

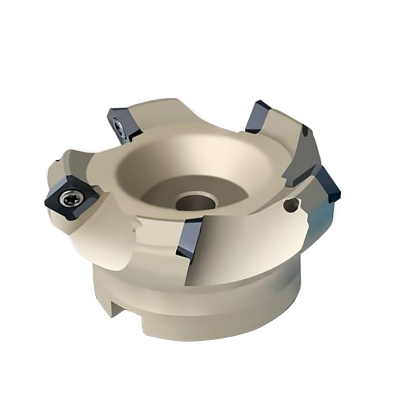

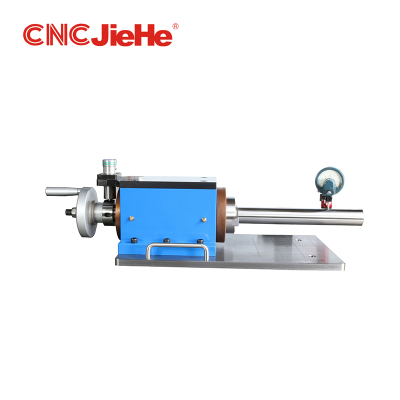

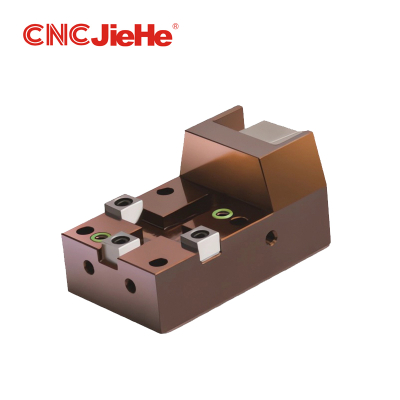

To adapt to the international market and meet customer needs, Jiehe Machinery will develop and produce spinning tool holders. The spinning tool holders will be mechanically rotated and compressed, generating radial pressure through a threaded structure.

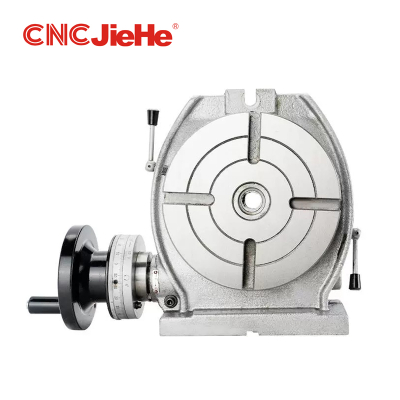

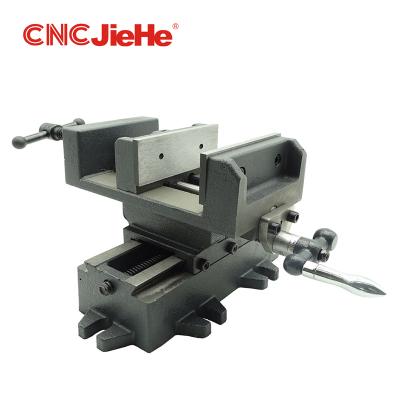

In the field of machining, the stability and anti-seismic performance of tools are key factors to ensure machining accuracy and efficiency. As a representative of high-precision machining tools, the unique design principle of the spinning anti vibration anti-vibration tool holder not only improves the stability of the tool during high-speed cutting, but also significantly enhances its anti vibration anti-vibration ability.

1、 The Core of Spinning Seismic Technology

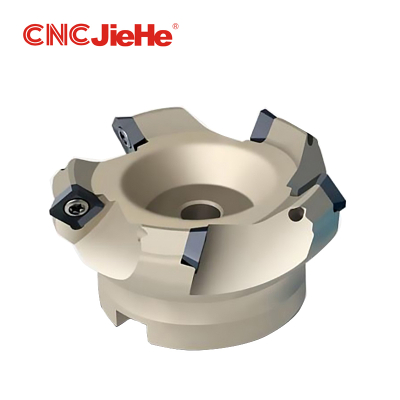

The core of the spinning anti-seismic tool holder lies in its unique spinning anti-seismic technology. This technology enables the tool holder to rapidly deform when subjected to cutting or impact forces through a precisely designed structure, but this deformation is not simply elastic deformation, but a carefully calculated small displacement opposite to the vibration direction. This displacement can effectively counteract vibration, thereby maintaining the stability of the cutting tool during the cutting process. In addition, the spinning seismic technology also improves the overall rigidity and strength of the handle by optimizing its material and structure, further enhancing its seismic performance.

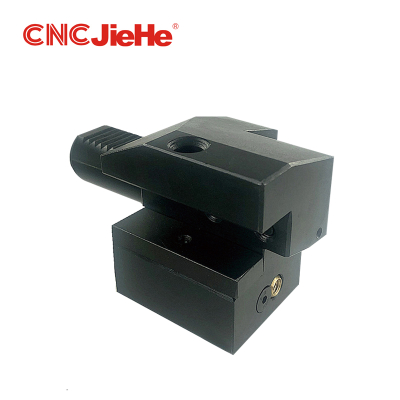

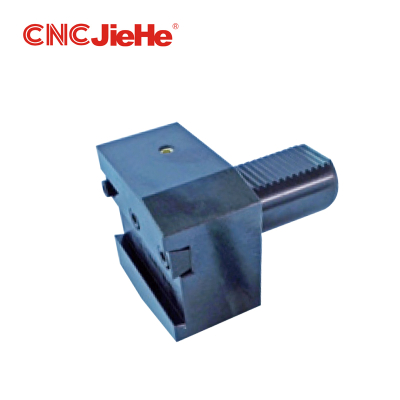

2、 The subtleties of structural design

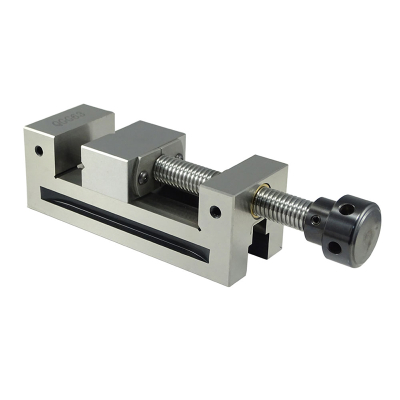

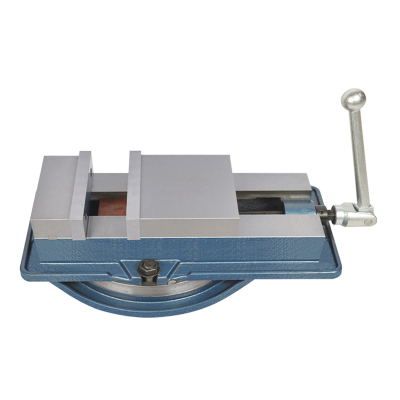

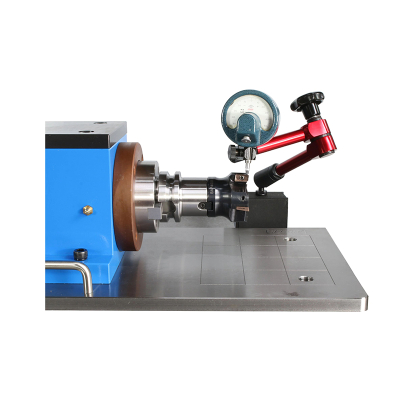

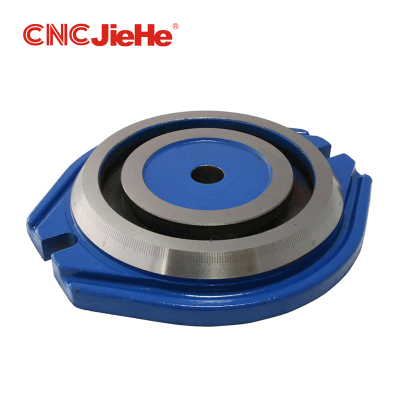

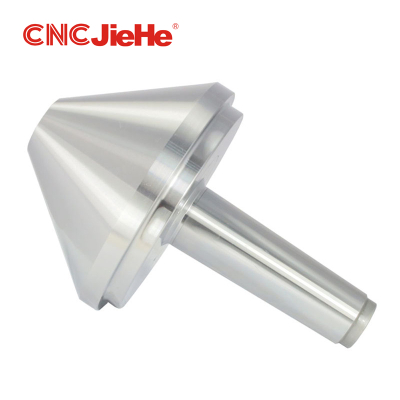

The structural design of the rotating anti-seismic handle is also exquisite. It usually consists of the handle body, handle end face, and handle cone surface. The handle body, as the main body, not only carries the weight of the tool, but also ensures a tight connection with the machine spindle through precision machining. The end face of the tool holder is precision machined to ensure contact accuracy with the machine spindle and reduce vibration caused by fit clearance. The taper surface of the tool holder adopts a standard 7/24 taper design, whichmatches the taper hole of the machine tool spindle to ensure the stability and rigidity of the tool holder in the spindle.

3、 Scientific considerations for material selection

In terms of material selection, a lot of effort have also been made in spinning the anti-seismic handle. It adopts high-quality alloy materials, which not only have high strength and hardness, but also excellent vibration resistance and wear resistance. The selection of alloy materials not only improves the overall performance of the handle, but also extends its service life and reduces maintenance costs. In addition, the surface of the tool handle may be coated with a special layer to enhance its corrosion resistance, hardness, and lubricity, further improving stability and efficiency during the machining process.

4、 Dynamic Balance and Precision Control

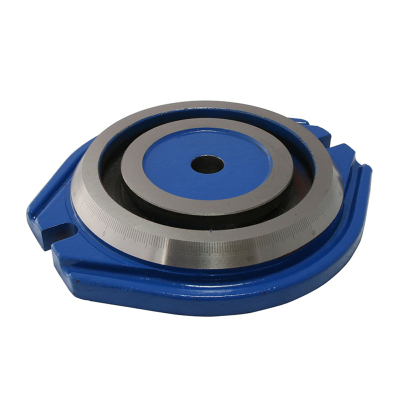

Dynamic balance is another important aspect of the design of spinning anti-vibration tool rest.By accurately calculating and adjusting the weight distribution of the handle, it achieves the optimal dynamic balance state to reduce vibration caused by imbalance. At the same time, the design of the tool holder also fully considers the requirements of machining accuracy. Through precise machining and assembly processes, it ensures that the tool holder can maintain a stable cutting trajectory and accuracy during the cutting process.